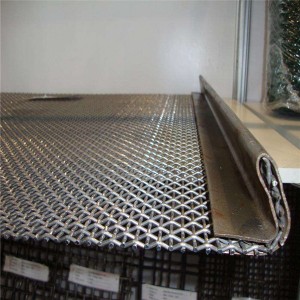

Mesh silig bararsanwaxaa loo isticmaalaa biyaha wasakhda ah, sifaynta saliida, macdanta, dhismaha, badbaadada iyo warshadaha cuntada lagu farsameeyo codsiyada u baahan xoog iyo shaandhaynta godad waaweyn iyo baadhis.Maro siligga ah oo horay loo crimped ayaa sidoo kale loo isticmaalaa codsiyada naqshadeynta dhismaha iyo warshadaha.

mesh silig waajib culuswaa caado loo sameeyay alaabada iyo codsiyada u baahan xoog iyo adag, sida shaandhada iyo warbaahinta shaandhaynta gariirka ee cabbirka, kala-soocidda iyo shaandhaynta walxaha culus ama waaweyn.Maro siligga ah oo culus ayaa loo isticmaalaa macdanta, sifaynta iyo warshadaha dhismaha.

Maro siligga ah oo hore loo crimp iyo mesh hawl culuswaxaa lagu soo saaraa dhexroorka siligga waaweyn.Waxaan bixinaa noocyo kala duwan oo bir ah iyo alloys si loogu isticmaalo mesh si loo buuxiyo shuruudaha alaabta.Ballaararka duubka-ballaaran ayaa diyaar ah.

Adeegyo beddelaad oo kala duwan ayaa jira.Kuwaas waxaa ka mid ah jeexid iyo xiirid, dhalaalid koronto, samaynta iyo alxanka, iyo samaynta caadooyinka.Haddii aad hayso wax su'aalo ah oo ku saabsan alaabtayada siliga hore ee curyaanka iyo culeyska culus, fadlan nala soo xiriir maanta.

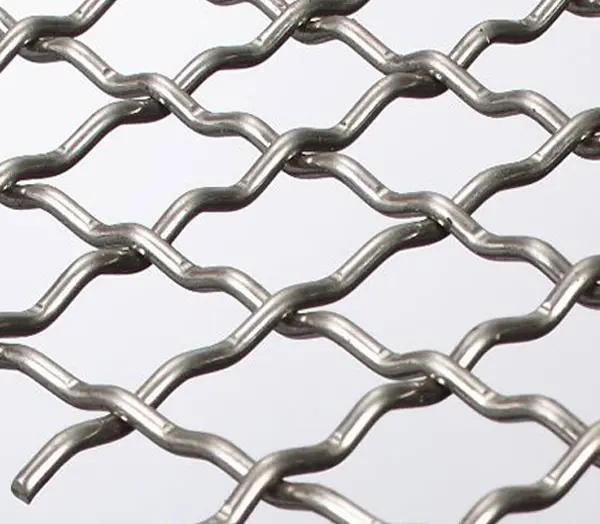

Silig-dhuuban oo laba-laab ah oo Crimp-ka Caadiga ah

Nooca ugu caansan ee siliga tolan.Waxaa loo adeegsadaa halka uu ka furmo uu yar yahay marka loo eego dhexroorka siliga.

Quful Crimp Wire tolan

Noocan siligga ah ee tolan waxaa loo isticmaalaa oo keliya qeexitaanno aan fiicneyn si loo ilaaliyo saxnaanta tolida inta lagu jiro nolosha shaashadda, halkaasoo furitaanku ku weyn yahay marka la eego dhexroorka siliga.

Inter Crimp Wire-xidhka

Waxaa loo adeegsadaa tillaabooyin aan fiicneyn oo ah silig tolan oo khafiif ah si loo helo xasillooni weyn, adkaanta tidnaanta iyo adkaanta ugu badan.Aad ayey ugu badan yihiin meelaha daahsoon mesh silig ka weyn 1/2" (12.7mm).

Filashka sare ee tolmada leh

Caadi ahaan waxay ka bilaabataa 5/8" (15.875 mm) furitaanka iyo ka weyn.Waxay bixisaa nolol adkeysi dheer leh, maadaama aysan jirin saadaasha dusha sare ee la xirto.Siliga tolman ee sare wuxuu bixiyaa caabbinta ugu yar ee socodka wuxuuna aad caan ugu yahay qaar ka mid ah codsiyada qaab dhismeedka iyo qaab dhismeedka halkaas oo dusha siman ee dhinac ka mid ah la jecel yahay.

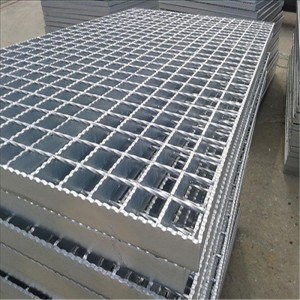

| Shaashad jilicsan oo sarreeya | |||||||||

| Maro muraayad jilicsan oo sarreeya oo caadi ahaan loo isticmaalo codsiyada waajibaadka culus ee maqaarka iyo cabbirka dhagaxyada, isku geynta, dhagaxa nuuradda, iwm | |||||||||

| Bir adag oo sarreeya—- Iska caabbinta abrasion | |||||||||

| Birta Aan Lahayn—- Iska caabinta Daxalka | |||||||||

| Monel,Brass,iwm — Codsiyada guud | |||||||||

| Tilmaamaha marada shaashadda | |||||||||

| Aperture | Duty Fudud | Waajibaad dhexdhexaad ah | Shaqo culus | ||||||

| tidde afar gees ah | silig dia kg/m2 OA% | silig dia kg/m2 OA% | silig dia kg/m2 OA% | ||||||

| 2 | 2 | 11.3 | 31 | ||||||

| 3.15 | 2 | 9.9 | 37 | 2.5 | 14.1 | 31 | |||

| 4 | 2 | 8.5 | 44 | 2.5 | 12.2 | 38 | 3.05 | 16.8 | 32 |

| 5 | 2 | 7.8 | 51 | 2.5 | 16.6 | 44 | 3.05 | 14.7 | 38 |

| 5.6 | 2.5 | 9.8 | 48 | 3.05 | 13.7 | 41 | 4 | 21.2 | 34 |

| 6.35 | 2.5 | 8.89 | 51 | 3.05 | 12.6 | 46 | 4 | 19.6 | 38 |

| 6.8 | 2.5 | 9 | 51 | 3.05 | 10 | 44 | 4 | 19.7 | 37 |

| 7.1 | 2.5 | 8.8 | 55 | 3.05 | 11.9 | 48 | 4 | 18.3 | 41 |

| 8 | 2.5 | 10.8 | 54 | 4 | 16.9 | 44 | 5 | 24.4 | 38 |

| 9 | 3.05 | 9.8 | 55 | 4 | 15.6 | 48 | 5 | 22.7 | 44 |

| 10 | 3.05 | 9.1 | 58 | 4 | 14.5 | 51 | 5 | 21.2 | 44 |

| 11.2 | 3.05 | 10.4 | 54 | 5 | 19.6 | 48 | 5.6 | 28.6 | 44 |

| 12.5 | 4 | 12.3 | 57 | 5 | 18.1 | 51 | 5.6 | 20 | 47 |

| 14 | 4 | 16.7 | 54 | 5 | 20 | 51 | 6.8 | 24.6 | 48 |

| 16 | 5 | 15.1 | 58 | 5.6 | 19.5 | 56 | 6.8 | 22.6 | 51 |

| 18 | 5 | 14.5 | 58 | 6.8 | 20.7 | 55 | 7.1 | 25 | 51 |

| 20 | 5.6 | 14 | 61 | 6.8 | 19.2 | 58 | 7.1 | 24 | 54 |

| 22 | 5.6 | 17.6 | 61 | 7.1 | 21.5 | 57 | 8 | 26.7 | 54 |

| 25 | 6.8 | 16.1 | 64 | 7.1 | 20.1 | 60 | 8 | 24.6 | 57 |

| 28 | 7 | 14.7 | 63 | 8 | 19 | 61 | 9 | 27.8 | 57 |

| 32 | 8 | 20.6 | 64 | 9 | 26 | 60 | 10 | 30.4 | 58 |

| 38 | 8 | 18.7 | 67 | 9 | 28.1 | 64 | 10 | 27.9 | 61 |

| 40 | 9 | 21 | 67 | 10 | 25.4 | 64 | 11.2 | 31.1 | 61 |

| 45 | 9 | 19.5 | 69 | 10 | 23.4 | 67 | 11.2 | 28.4 | 64 |

| 50 | 10 | 23.2 | 69 | 11.2 | 26 | 67 | 12.5 | 31.8 | 64 |

| 56 | 10 | 19.2 | 72 | 11.2 | 28.7 | 69 | 12.5 | 29 | 67 |

| 63 | 10 | 17.4 | 75 | 11.2 | 24.5 | 72 | 12.5 | 25.1 | 70 |

| 76.2 | 10 | 14.8 | 78 | 11.2 | 16 | 75 | 12.5 | 20 | 73 |

| 80 | 10 | 16 | 79 | 11.2 | 17.5 | 72 | 12.5 | 21.5 | 75 |

| 90 | 10 | 14 | 81 | 11.2 | 15.7 | 79 | 12.7 | 19.4 | 77 |

| 100 | 10 | 10 | 82 | 11.2 | 14.3 | 81 | 12.7 | 17.6 | 79 |